Description

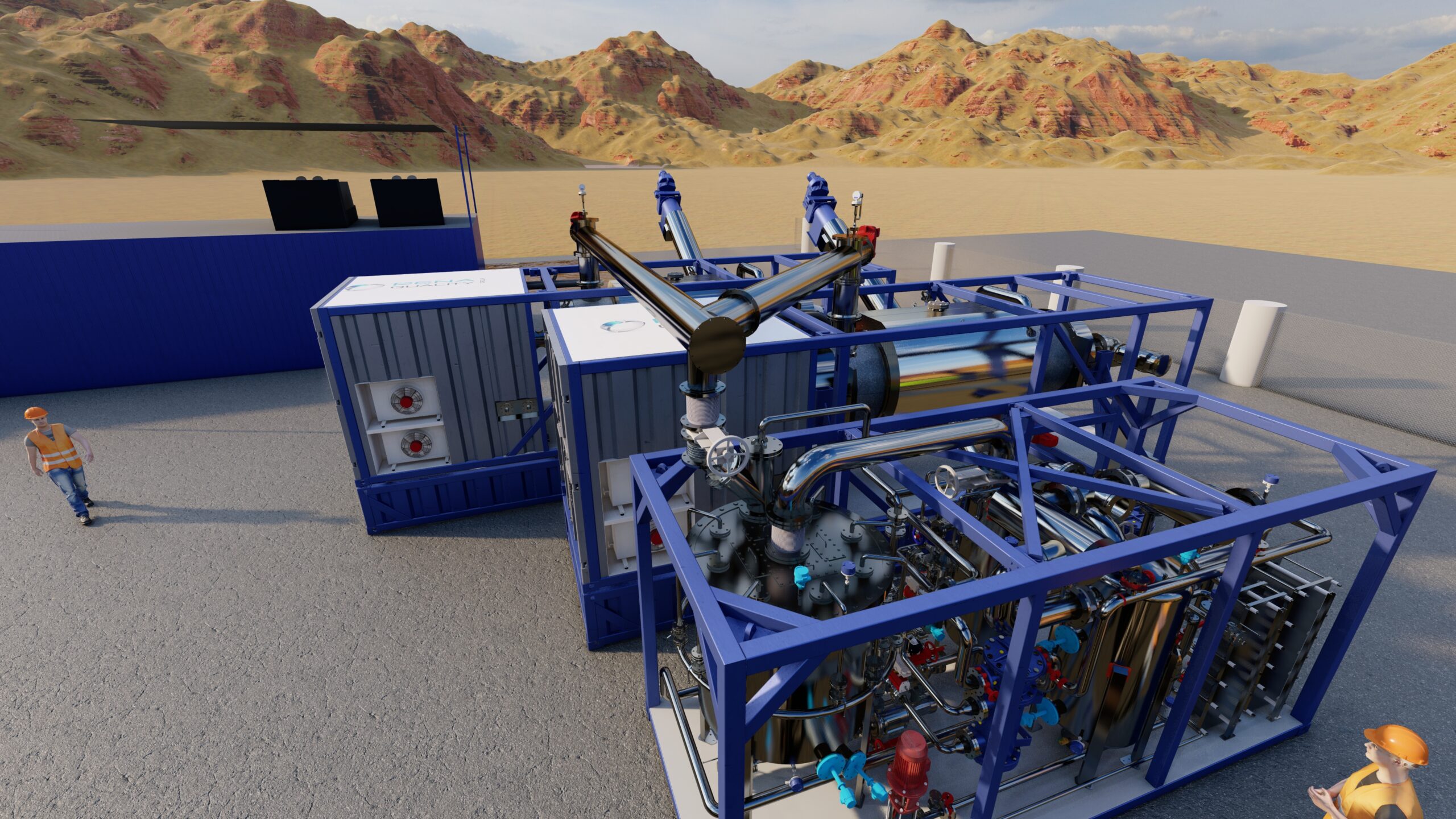

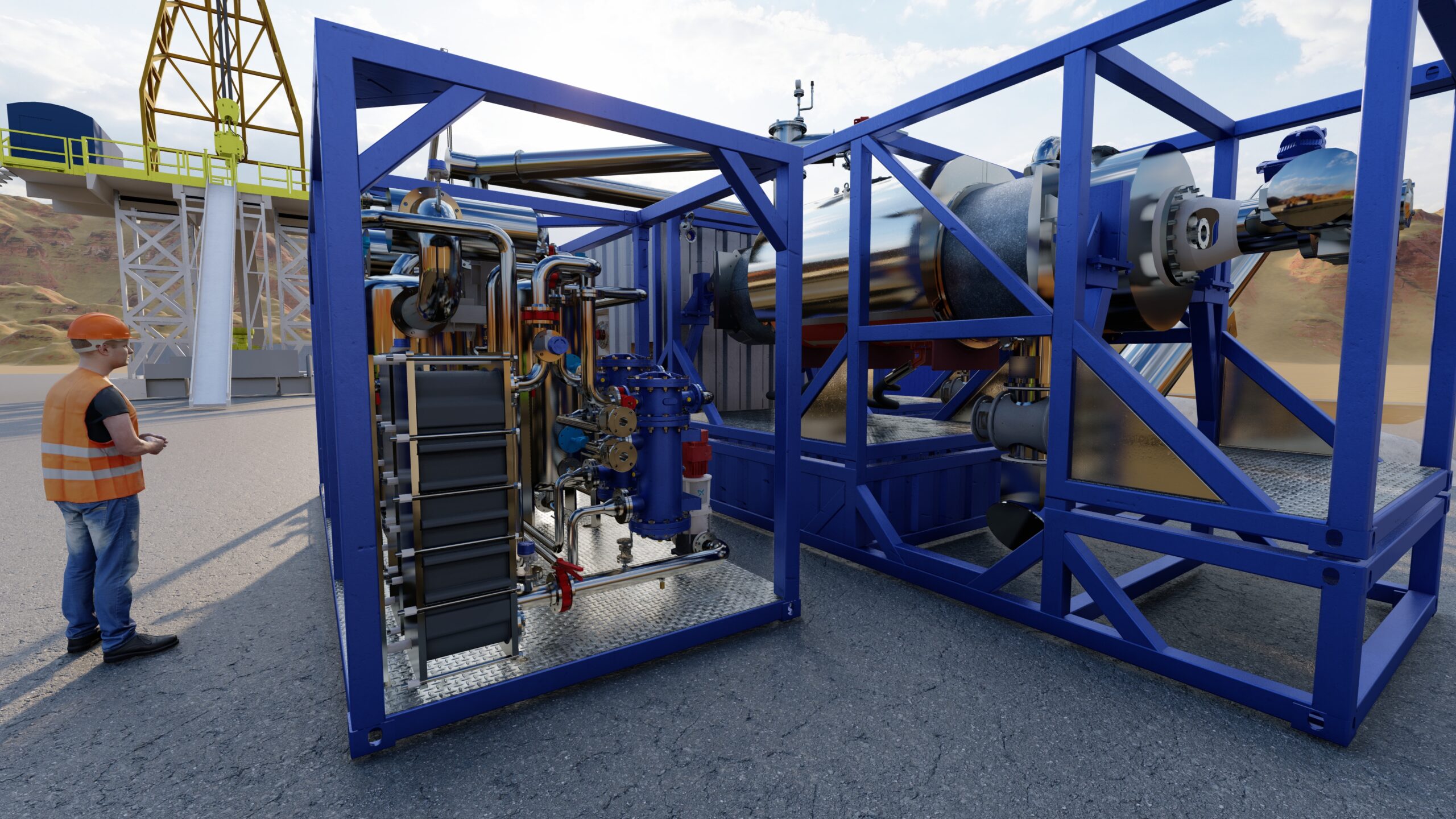

The Induction Thermal Desorption Unit (ITDU) from Eagle Technology AS is designed for processing of oil contaminated drilling waste such as drill cuttings and slop-mud. With its advanced technology, this unit uses induction to raise the temperature above the boiling point of water and oil, allowing hydrocarbons to be reclaimed while discharged solids meet most offshore discharge regulations globally.

One of the key advantages of the ITDU is its mobility. It can be transported easily to any location where drilling waste needs to be processed, making it a versatile and convenient solution for oil and gas companies. Additionally, it operates 24/7, ensuring that waste is processed efficiently and without any downtime. Another significant advantage of the ITDU is its minimum power consumption. This means that it is not only cost-effective to operate but also more environmentally friendly than other waste processing methods. Additionally, the ITDU is easy to operate, and only requires two operators per shift, one of whom can operate it remotely.

The ITDU is capable of treating drill cuttings to less than 0.5%, which means that the waste is almost completely cleaned, making it suitable for offshore discharge. The unit can also process viscous drill cuttings from old cuttings pits, which are notoriously difficult to treat. Finally, the ITDU has a heat energy surplus, which can be used for other processes or applications.

In conclusion, the Induction Thermal Desorption Unit from Eagle Technology is a highly efficient, mobile, cost-effective, and environmentally friendly solution for the processing of oil contaminated drilling waste. With its advanced technology, it offers significant advantages over traditional waste processing methods, making it an excellent investment for oil and gas companies looking to reduce their environmental impact while increasing efficiency.

Currently our pilot unit is fully operational and generating impressive performance data at Averøya, Norway. During March 2023, we were able to process over 2000 tonnes of drill cuttings.

For further information, please contact:

Pål Vidar Stokvik

Chief Commercial Officer

(+47) 413 04 760 | pvs@eagle.no