Description

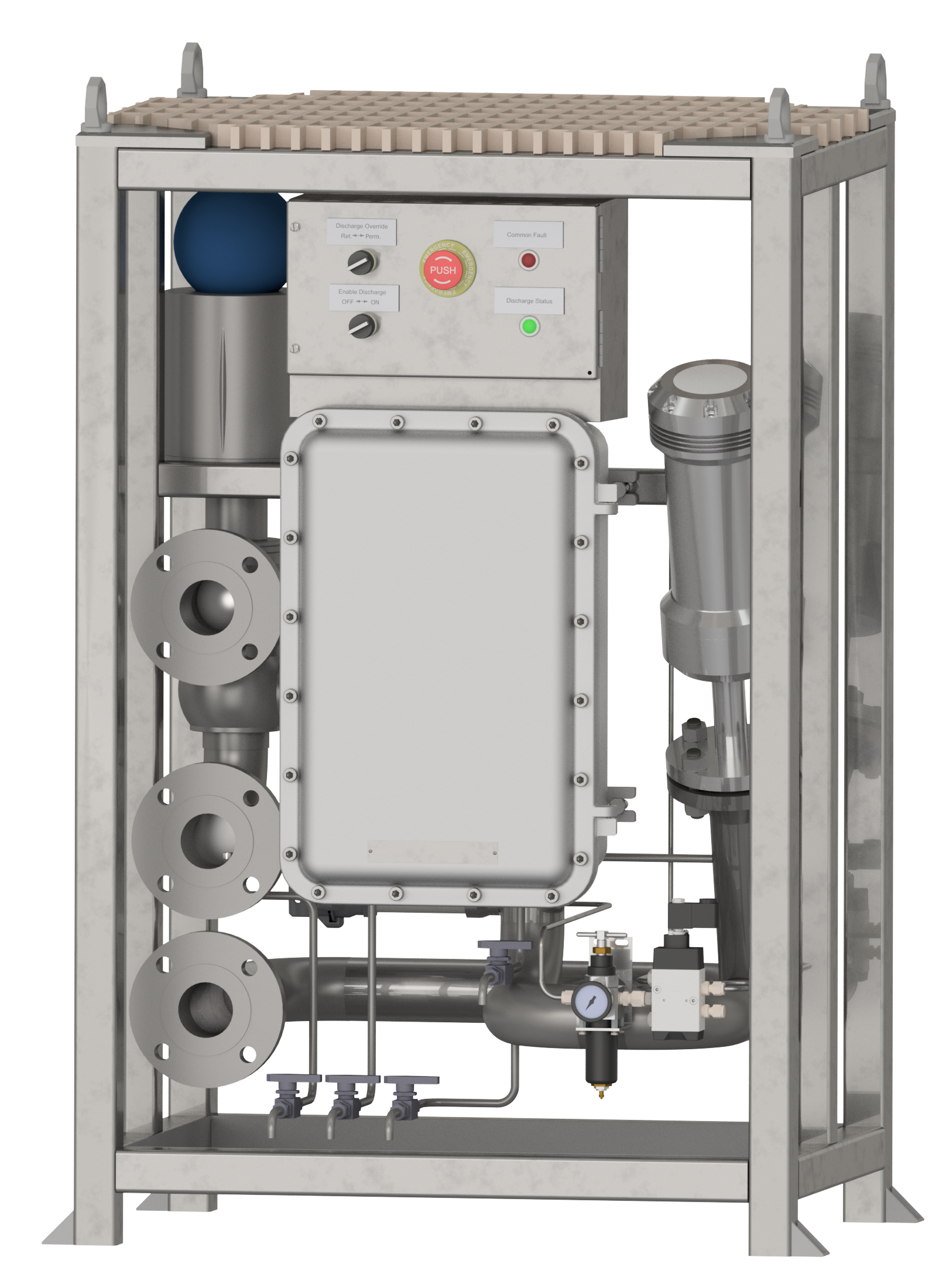

Eagle Oil in Water Measurement and Liquid Control skid, a solution for detecting and controlling the amount of oil in water in your industrial processes. Our skid is stand-alone and comprises a control enclosure, a 3-way valve, and a high-precision measuring device that uses laser-induced fluorescence to detect the amount of oil in water in real-time.

Our skid is certified for ATEX zone 1 and requires only a 230VAC power connection and a 6-10 bar instrument air connection to function, making it a low-consumption and low-maintenance solution for your business. The skid is designed to be compact, measuring just 1.33m x 0.83m x 0.61m (H x W x D), and comes with a control cabinet that features a PLC, operator panel, and PPM readout screen.

The function of the skid is to determine if a liquid flowing through the unit contains oil above or below a certain limit, which can be set according to requirements. Based on the amount of oil detected, the unit will discharge the liquid to one of two designated outlets – the reject outlet or the clean water outlet. The position of the valve controlling the discharge direction is monitored by the control system, which will trigger an alarm in the event of valve malfunction.

The measuring device of the unit is a high-reliability, high-precision, and compact probe-style in-line measuring system that provides several necessary advantages. It eliminates chemical interference that occurs in 99% of applications, offers oil type detection that enables the analyzer to automatically select the correct calibration curve, and verifies that the analyzer is reading accurately despite process changes. Additionally, the skid features a new rapid wave ultrasonic self-cleaning technology that automatically keeps the sensor clean and does not affect process readings.

The Eagle Oil in Water Measurement and Liquid Control skid is also designed with remote monitoring capabilities. It features a common fault potential free contact, a discharge active status potential free contact, and a current oil in water content 4-20mA active signal that could be used for logging or external monitoring. The skid can also be connected to a standard CAT5/CAT6 cable to view the PPM readout directly in a control room.

For further information, please contact:

Pål Vidar Stokvik

Chief Commercial Officer

(+47) 413 04 760 | pvs@eagle.no